Innovation in Custom Assembly: Building, Testing, and Refurbishing Ground & Jumpers

Key Takeaways

- Advancements in technology have streamlined the building and testing of custom ground and jumper assemblies, improving efficiency, quality, and scalability.

- Ongoing testing and timely refurbishment are essential for preserving electrical systems’ safety, functionality, and regulatory compliance.

- Adhering to industry standards and pursuing certifications is paramount for ensuring product reliability and instilling confidence among clients and governing authorities.

Table of Contents

- Introduction

- Advancements in Assembly Construction

- Importance of Regular Testing

- Refurbishment for Extended Lifespan

- Industry Standards and Certifications

- Future Trends in Ground and Jumper Assemblies

Introduction

In the dynamic and highly regulated energy industry, ensuring safety and maintaining system reliability are non-negotiable priorities. Custom ground and jumper assemblies are key elements supporting this stability, which play a crucial role in preserving electrical continuity, protecting personnel, and safeguarding critical equipment. With the advancement of technology, the processes for constructing, testing, and refurbishing these components have evolved significantly. Modern assemblies are now built to meet higher standards of durability and efficiency, incorporating materials and designs that promote long-term use and sustainability.

For energy professionals and organizations aiming to uphold the highest safety and operational performance levels, staying informed about current practices and innovations is essential. Resources like https://divergentalliance.com/electrical-equipment-testing-refurbishing/ provide insights into specialized testing, refurbishing solutions, and industry trends supporting these vital systems’ ongoing development and maintenance.

Remaining abreast of the latest industry developments and regularly consulting reputable sources is essential for anyone responsible for maintaining or upgrading electrical assemblies. Prioritizing innovative methods from assembly line automation to precise, data-driven testing protocols can substantially lengthen system lifespan, minimize risk, and guarantee ongoing compliance with a rapidly changing set of industry norms. For those seeking structured guidance or proven solutions in this landscape, trusted partners stand ready to assist with best practices, robust technical insights, and access to the forefront of electrical systems technology. By leveraging current expertise and technology-driven strategies, organizations can transform their maintenance routines from reactive to proactive, ensuring safe, efficient, and future-ready operations.

Advancements in Assembly Construction

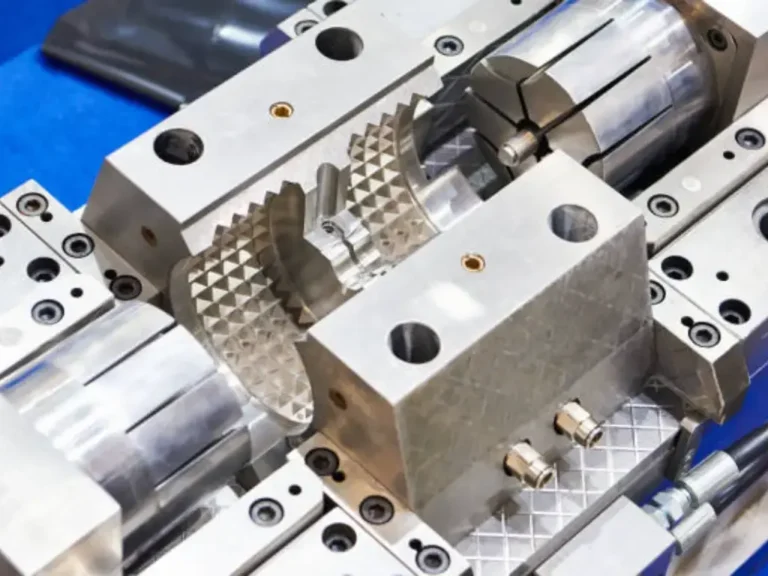

The construction and design landscape for custom ground and jumper assemblies has transformed dramatically with recent advances in both automation and materials engineering. Today’s manufacturers employ highly sophisticated automated machinery, including precision cable processors like the Schleuniger Cut & Strip machine, to achieve previously unattainable accuracy in stripping, crimping, and assembly preparation. This high level of automation ensures not only a consistent output but also enables rapid scaling to meet urgent and large-scale project demands, maintaining exceptional reliability throughout.

Beyond the machinery itself, new developments in insulation technology, conductor strand optimization, and robust connector designs have propelled modern assemblies far ahead of their predecessors. Enhanced insulating materials now provide greater protection from moisture, chemicals, and extreme temperature fluctuations, significantly reducing the potential for premature failures. Additionally, increased strand counts and reinforced hardware yield assemblies that are both highly flexible and incredibly strong, making them better equipped to cope with challenging installations and harsh operating environments.

Ultimately, these advancements mean less downtime, fewer unscheduled repairs, and greater peace of mind for plant managers, engineers, and field technicians. By continuously adopting such innovative assembly construction techniques, forward-thinking organizations position themselves at the leading edge of system reliability and performance.

Importance of Regular Testing

Even the most technologically advanced ground and jumper assemblies rely on regular, comprehensive testing to ensure ongoing safety and optimum performance. The integrity of these assemblies is closely linked to workplace safety and uninterrupted facility operations; thus, regular testing schedules cannot be ignored. Industry best practices dictate rigorous inspection routines at least annually, or even more frequently for assemblies exposed to harsh environments, fluctuating loads, or physical wear.

Effective testing is multi-faceted, combining high-voltage dielectric tests for insulation integrity, precision resistance measurements to monitor connection and cable health, and thorough visual inspections to detect physical signs of wear, burns, corrosion, or contamination. By identifying issues early, testing protocols minimize the risk of catastrophic outages or unforeseen equipment failure, safeguarding human health and production assets.

Notably, having structured testing documentation and repeatable protocols allows for rapid identification of fault patterns, enhancing both preventative maintenance strategies and the overall effectiveness of asset management programs. Consistent testing underpins all efforts to maintain regulatory compliance and extend assembly service life.

Recommended Testing Protocols

- Dielectric testing for insulation verification, exposing potential weaknesses invisible to the naked eye

- Detailed visual inspection for signs of wear, corrosion, contamination, or required cleaning

- Resistance testing for confirmation of continuity and solid, low-impedance connections

- Meticulous documenting and reviewing of test results to guide future maintenance and troubleshooting

Refurbishment for Extended Lifespan

Refurbishment stands out as both an eco-friendly and economically sound strategy for extending the useful lifespan of ground and jumper assemblies. Instead of scrapping entire assemblies when only partial elements have experienced degradation, knowledgeable service providers target replacement and repair efforts where they are most needed—be it at cable ends, connectors, or damaged insulation sheaths. Incorporating refurbishment services can restore even heavily used assemblies to like-new performance, a process backed up by modern diagnostic and testing methodologies.

This approach not only helps cut operational expenses by avoiding unnecessary replacements but also maximizes return on investment by squeezing greater life out of each asset. The sustainability dimension is equally compelling, as refurbishment substantially diminishes the volume of cable waste destined for landfill. In addition, refurbished assemblies provide operational agility, as these restored components can be swiftly integrated back into service or repurposed elsewhere depending on dynamic project requirements.

For organizations committed to sustainable growth and prudent risk management, integrating refurbishment into lifecycle maintenance plays a key role in balancing cost, performance, and environmental responsibility.

Key Steps in Refurbishment

- Comprehensive initial inspection of complete assemblies to isolate potential issues

- Replacing malfunctioning, worn, or obsolete hardware with up-to-date, certified components

- Restoring or upgrading insulation, jackets, and cable sheathing to prevent premature wear

- Executing a battery of repeat tests to guarantee restored integrity and conformance to standards

Industry Standards and Certifications

Ensuring compliance with authoritative industry standards is fundamental in securing the’ safety, reliability, and durability of ground and jumper assemblies. Organizations like ASTM International and the Occupational Safety and Health Administration (OSHA) prescribe detailed requirements for both the materials used and the processes followed during manufacturing, assembly, and ongoing maintenance. Achieving adherence is not merely for regulatory fulfilment it’s essential for risk reduction, liability management, and operational excellence.

Furthermore, third-party certifications play a pivotal role in validating the dependability of assemblies. Certified products undergo exhaustive third-party inspection, failure-mode analysis, documentation review, and chain-of-custody verification adding layers of credibility that are indispensable for utilities, contractors, and large-scale industrial operators. For anyone seeking deeper insights into this area, the OSHA Electrical Standards and guidance from ASTM International provide extensive resources on safety benchmarks and material specifications.

Ultimately, by choosing assemblies that have passed rigorous regulatory and certification requirements, organizations can both meet legal obligations and build trust with stakeholders by ensuring best-in-class reliability.

Future Trends in Ground and Jumper Assemblies

Looking ahead, the trajectory for ground and jumper assemblies is set firmly on a path toward digital transformation, advanced materials science, and intelligent diagnostics. Incorporating artificial intelligence (AI) and sophisticated sensors enables predictive analytics, early warning of component degradation, and optimized maintenance schedules, paving the way for smarter, faster, and safer operations across electrical infrastructure.

On the materials front, innovators are developing breakthrough insulation and conductive materials such as high-performance thermoplastics and ultra-lightweight composites that offer increased flexibility, higher resistance to adverse environments, and longer operating lives. These next-generation designs accommodate the ever-tightening installation spaces found in modern electrical grids, renewable energy installations, and complex data centers.

For organizations aiming to future-proof their operations, investing in ongoing employee training, actively monitoring the latest trends, and partnering with innovative suppliers is key to adapting quickly and maintaining a leadership position in the market. Proactive adaptability, bolstered by collaboration with leading industry experts and resources, ensures readiness in an era of unprecedented transformation.

Also Read-Master Energy Management Using Smart Visualization Technology